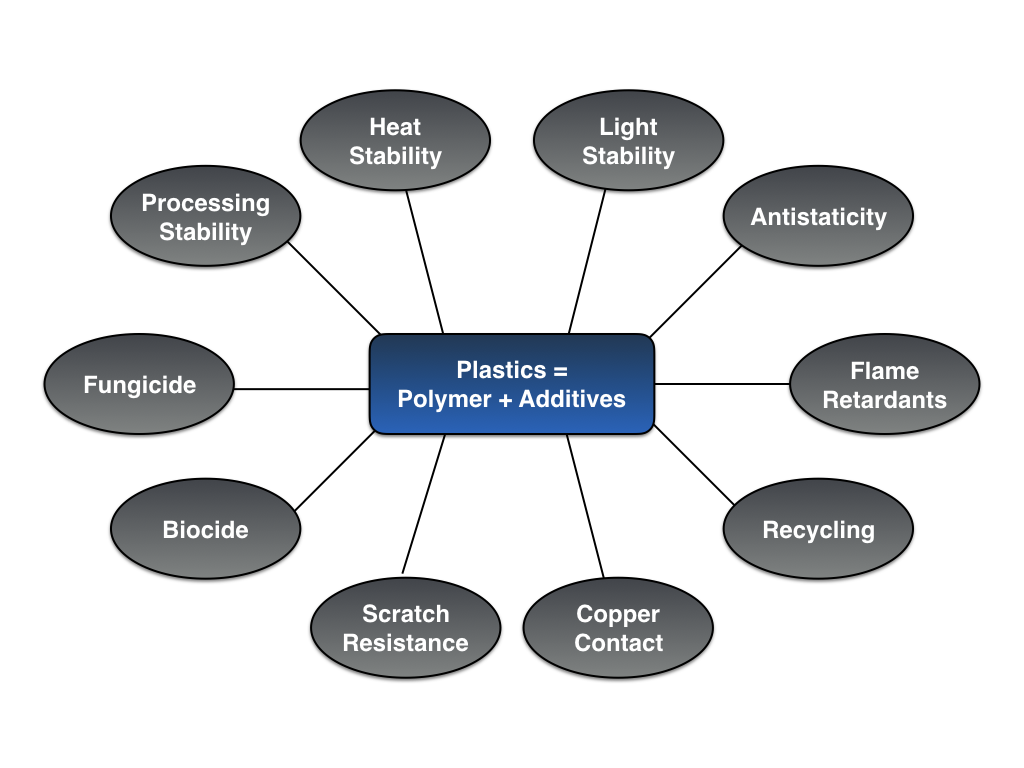

Polymer Additives

Improve mechanical properties, processing, durability.

- Fillers:

Added to Improve tensile strength & abrasion resistance, toughness & decrease cost.

Examples: Carbon black, Silica gel, Wood flour, Glass, Limestone, Talc. - Plasticizers:

Added to reduce glass transition temperature Tg below room temperature. Presence of plasticizer transforms brittle polymer to a ductile one. Commonly added to PVC. - Stabilizers:

Antioxidants, UV protection - Lubricants:

Added to allow easier processing polymer “slides” through dies easier (sodium stearate). - Colorants:

Dyes and pigments - Flame Retardants:

Substances Containing Chlorine, Fluorine and Boron.

Physical Form

Suppliers

Faci Group

Italy

Chemical Mate

Malaysia

Faster Capital

Italy

Clariant

KSA

Al-Kooheji Petroglobe

Bahrain

SABO

Italy

McKinn

Singapore

Greenchemicals S.p.A

Italy

Clients

Polymer Manufacturers

Sabic

Tasnee

Sahara

Petrorabigh

Saudi Chevron S-Chem

NatPet

Advanced Petrochemical Company

Borouge

Equate

Orpic

OPC

Clients

One Pack Producers

GSI – Gulf Stabilizer Industries

BASF

M.J Additives

Adeka

Songwon

Ingenia

Clients

Master Batch Producers

Clariant

RAVAGO

Polytec Masterbatch LLC

Enerplastic